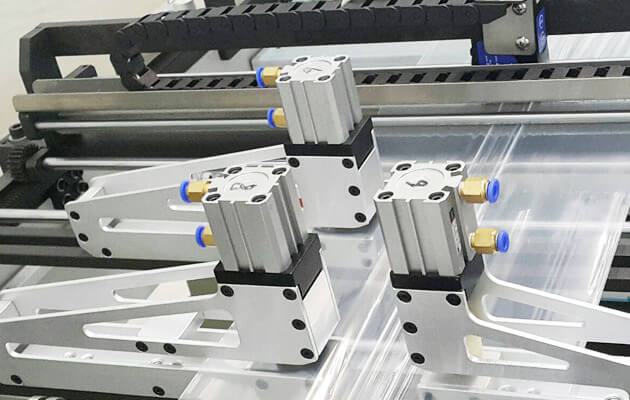

Slit Seal Blades

Posted : admin On 4/15/2022This hot knife Slit Seal Unit utilizes small, heated blades to penetrate and seal plastic film as it is passed over the blade. It operates with a 120Vac 50/60Hz power, and includes a 6' power cord. Please contact us to review your order for a 916 Slit Seal Unit. Replacement Parts. Aluminum Clamp (CSI-B101-179) Copper Stud (CSI-A101-059). #6 Slit Seal – Heavy Duty Slit Seal Blade for 2 to 3 mil low density film About Bag Machine Parts, a subsidiary of Modern Manufacturing Services LLC, offers the largest selection of bag machine parts and converting equipment accessories through in-house manufacturing and a vast network of suppliers across the world. Slit Seal Our Slit Seals are very suitable when it comes to sealing two or more layers of film together in the machine direction. The slit-seal technique is usually used to convert a single large tube of film into smaller tubes.

Every day thousands of different end products are packaged for resale. From form, fill and seal horizontal and vertical baggers, pouches, shrink-wrappers, over-wrappers, automatic carton tapers and sealers to vacuum packaging, virtually all types of packaging processes rely on a blade to make the final cut. And Hyde has been supplying blades to cut, slice, slit and chop, helping package the products we buy for decades.

As a user, you realize that today’s packaging requirements provide cutting challenges never before realized. In a very competitive industry that is constantly evolving, efficiency and profitability are key performance measures upon which you are judged. Frequently shutting down equipment due to blade failure is costly and unacceptable. You have helped us gain the experience necessary through years of applications engineering to recommend specifications that will extend blade life, resulting in increased productivity and yield. This in turn will boost your bottom line.

Some of the more common cutting knives used by a variety of packaging processes include:

Slit Seal Blades Parts

- Case sealer knives

- Tape knives

- Bagger knives

- Zig-zag knives

- Perforators

- Slicer knives

- Gloucester blades

- Form-fill-seal knives

- Cross-cut knives

- Crush cutters

- Tear-slot knives

- Flow-wrapper knives

Steel choice, edge style, bevel angle, edge thickness, surface micro finish, hone technique, flatness… all are critical functions that will affect the performance of the blades you use in your packaging operations. Tell us what your cutting challenges are and we’ll build you a blade that overcomes those challenges. With over a century of experience in providing you the right specifications to optimize performance, you can count on Hyde knives.

With in-house laser cutting capabilities, we can cut virtually any shape you can imagine without expensive tooling. On-site, state of the art heat treating equipment ensures a controlled process, giving you the assurance you need that the blades you use are as flat as can be.

With many types of alloys that are formulated to meet the stringent demands faced by today’s packaging operations in stock, you can get the performance you need when you need it. Tolerances are monitored closely to ensure that our blades and knives are easy to set up and tune, so you are up and running as fast as possible. Hyde blades deliver long life and consistent performance, helping to drive efficiency and profitability – your bottom line.

Slit Seal Blades Home Depot

There’s a fine line between edge performance and durability, and we provide products that address both of those requirements. So if you slit it, trim it or cut it to length, Hyde blades give you cutting edge performance.